A Huge Advantage For The Custom Parts Market!

Moldless System is a specific production system that does not employ metallic molds. Using this system, it is possible to make products for which metallic molds were previously considered indispensable, as well as products that are impossible to make using metallic mold technology. In addition, Moldless system can reduce initial production costs while shortening the time required for production.

Traditional Mold Production

High cost of mold

High minimums

Long lead times

Revisions require new mold and therefore very costly

Materials & hardnesses are limited

Moldless Manufacturing

No investment cost

No minimum

Short lead times

Parts are easy to revise

Large variety of materials & harnesses

Of course, in the case of mass production, there are cases where the use of metallic molds is more efficient. However, the Moldless System is ideal for order-made products and small quantity production runs such as for prototyping, trial products and products with complex shapes that cannot be formed using a metallic mold.

The process offers order-made products with complex shapes and makes them in small quantities. We can do this, thanks to the unique Moldless System, which is highly efficient and cost effective method.

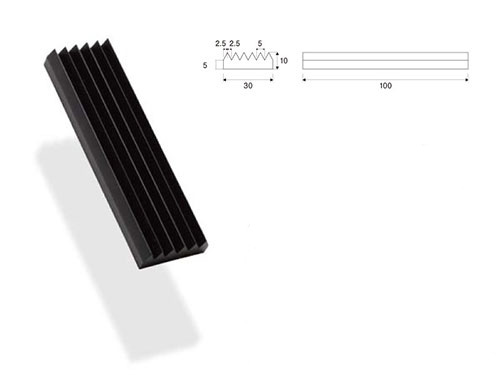

Lathe Machining

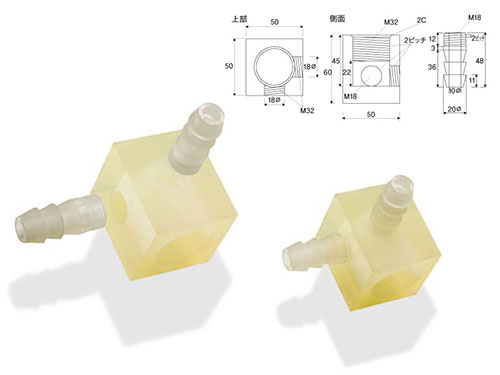

Compound Process

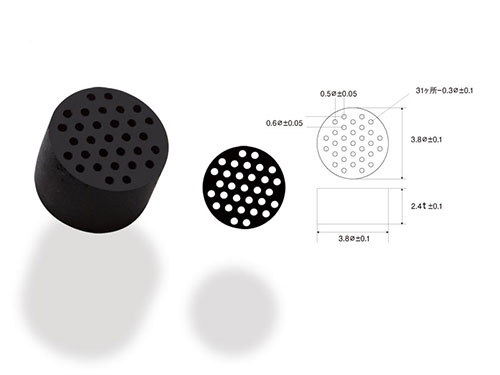

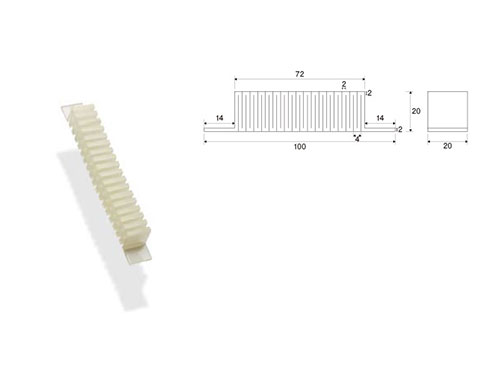

Waterjet Cutting - Micro Drilling - Solid Block Fabrication - Plural Process

Please note: Ragco affiliates have full autonomy to provide services that best suit their respective markets. Please check with your local Ragco location to learn what capabilities they offer. Find the closest affiliate to you here.